How do self-adhesive labels balance adhesion and residue-free removal?

Release Time : 2025-12-25

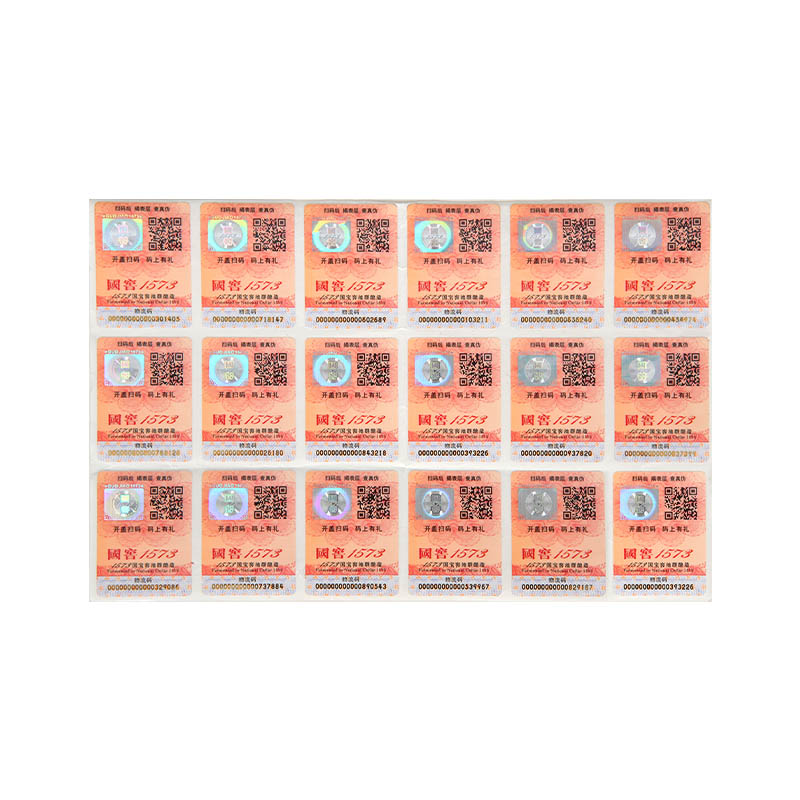

Self-adhesive labels are ubiquitous in daily life—from production information on food packaging to brand logos on cosmetic bottles, and energy efficiency stickers on appliance casings. They must adhere firmly to various surfaces, withstanding transportation, storage, and even refrigeration and sunlight; yet, they must also be easily removed in specific situations, leaving no residue and without damaging the substrate. This seemingly contradictory requirement—"adhesive adhesion and easy removal"—is the core breakthrough of modern self-adhesive label technology. It doesn't rely on a single strong adhesive, but rather on a precise synergy between adhesive formulation, surface material selection, and structural design to find the perfect balance between "adhesion" and "removal."

The key lies in the intelligent responsiveness of the adhesive. Traditional strong adhesives are difficult to remove once applied, while modern self-adhesive labels use pressure-sensitive adhesives (PSA) with "controllable adhesion." These types of adhesives can quickly form sufficient adhesion at room temperature and pressure, ensuring that labels do not curl or fall off during normal circulation. However, when a slow, uniform peeling force is applied, their molecular chain structure can disintegrate in an orderly manner, avoiding breakage and residue. Furthermore, for the need for "markless removal," engineers adjust the ratio of cohesive force to adhesion force of the adhesive layer—making the adhesive's own bonding force slightly stronger than its bonding force with the object being applied, thus achieving complete peeling without leaving any marks.

Secondly, the matching of the face material and the backing paper is also crucial. Different face materials, such as transparent PET, matte PVC, or specialty paper, have surface properties and flexibility that directly affect the bonding effect. For example, on smooth glass or metal surfaces, high-transparency PET labels with low initial tack provide both invisible adhesion and easy removal later; while on curved plastic bottles, flexible face materials with medium-holding adhesive are needed to ensure a smooth fit while maintaining removability. The uniformity of the silicone oil coating on the backing paper also affects adhesive transfer—high-quality backing paper releases stable adhesive, avoiding uneven adhesive application that leads to localized residue.

Furthermore, application scenarios drive functional segmentation. Not all "seamless" labels mean "weak adhesion." Some labels need to adhere firmly for months, requiring clean removal only during recycling or repair; others are used for temporary promotional pricing, needing to be applied and removed immediately. To address this, manufacturers have developed various adhesive types: "removable" for short-term labeling; "permanent but clean-removable" for long-term applications requiring post-processing; and "low-temperature removable" specifically designed for frozen foods. This ability to customize allows the same product type to precisely match different lifecycle needs.

In addition, environmental and safety considerations are also incorporated. High-quality self-adhesive labels use solvent-free and heavy metal-free adhesives, ensuring no harmful substances are released even after contact with food packaging or children's toys. Simultaneously, the removable design itself promotes sustainability—after consumers easily remove the label, the container is easier to clean and recycle, reducing material degradation caused by adhesive residue.

At a deeper level, this "combination of rigidity and flexibility" reflects modern materials science's profound understanding of user experience. It respects the user's dual identity: both the user of the product and a potential recycler or reuser. Labels are no longer a one-time application, but a flexible node in the product's entire lifecycle.

Ultimately, the ability of self-adhesive labels to be both durable and residue-free is not magic, but a sophisticated fusion of chemistry, physics, and industrial design. It clearly conveys brand information and then quietly disappears after its mission is complete, leaving no trace. When an empty bottle of skincare product has its label easily removed, ready to be filled into a travel-sized container; when an old appliance is returned for repair, the label can be peeled off intact without damaging the casing—at that moment, the small label has fulfilled its dual mission: steadfastly protecting the product while gracefully bidding farewell. This is the gentlest wisdom of modern labeling technology.

The key lies in the intelligent responsiveness of the adhesive. Traditional strong adhesives are difficult to remove once applied, while modern self-adhesive labels use pressure-sensitive adhesives (PSA) with "controllable adhesion." These types of adhesives can quickly form sufficient adhesion at room temperature and pressure, ensuring that labels do not curl or fall off during normal circulation. However, when a slow, uniform peeling force is applied, their molecular chain structure can disintegrate in an orderly manner, avoiding breakage and residue. Furthermore, for the need for "markless removal," engineers adjust the ratio of cohesive force to adhesion force of the adhesive layer—making the adhesive's own bonding force slightly stronger than its bonding force with the object being applied, thus achieving complete peeling without leaving any marks.

Secondly, the matching of the face material and the backing paper is also crucial. Different face materials, such as transparent PET, matte PVC, or specialty paper, have surface properties and flexibility that directly affect the bonding effect. For example, on smooth glass or metal surfaces, high-transparency PET labels with low initial tack provide both invisible adhesion and easy removal later; while on curved plastic bottles, flexible face materials with medium-holding adhesive are needed to ensure a smooth fit while maintaining removability. The uniformity of the silicone oil coating on the backing paper also affects adhesive transfer—high-quality backing paper releases stable adhesive, avoiding uneven adhesive application that leads to localized residue.

Furthermore, application scenarios drive functional segmentation. Not all "seamless" labels mean "weak adhesion." Some labels need to adhere firmly for months, requiring clean removal only during recycling or repair; others are used for temporary promotional pricing, needing to be applied and removed immediately. To address this, manufacturers have developed various adhesive types: "removable" for short-term labeling; "permanent but clean-removable" for long-term applications requiring post-processing; and "low-temperature removable" specifically designed for frozen foods. This ability to customize allows the same product type to precisely match different lifecycle needs.

In addition, environmental and safety considerations are also incorporated. High-quality self-adhesive labels use solvent-free and heavy metal-free adhesives, ensuring no harmful substances are released even after contact with food packaging or children's toys. Simultaneously, the removable design itself promotes sustainability—after consumers easily remove the label, the container is easier to clean and recycle, reducing material degradation caused by adhesive residue.

At a deeper level, this "combination of rigidity and flexibility" reflects modern materials science's profound understanding of user experience. It respects the user's dual identity: both the user of the product and a potential recycler or reuser. Labels are no longer a one-time application, but a flexible node in the product's entire lifecycle.

Ultimately, the ability of self-adhesive labels to be both durable and residue-free is not magic, but a sophisticated fusion of chemistry, physics, and industrial design. It clearly conveys brand information and then quietly disappears after its mission is complete, leaving no trace. When an empty bottle of skincare product has its label easily removed, ready to be filled into a travel-sized container; when an old appliance is returned for repair, the label can be peeled off intact without damaging the casing—at that moment, the small label has fulfilled its dual mission: steadfastly protecting the product while gracefully bidding farewell. This is the gentlest wisdom of modern labeling technology.